Product Description:

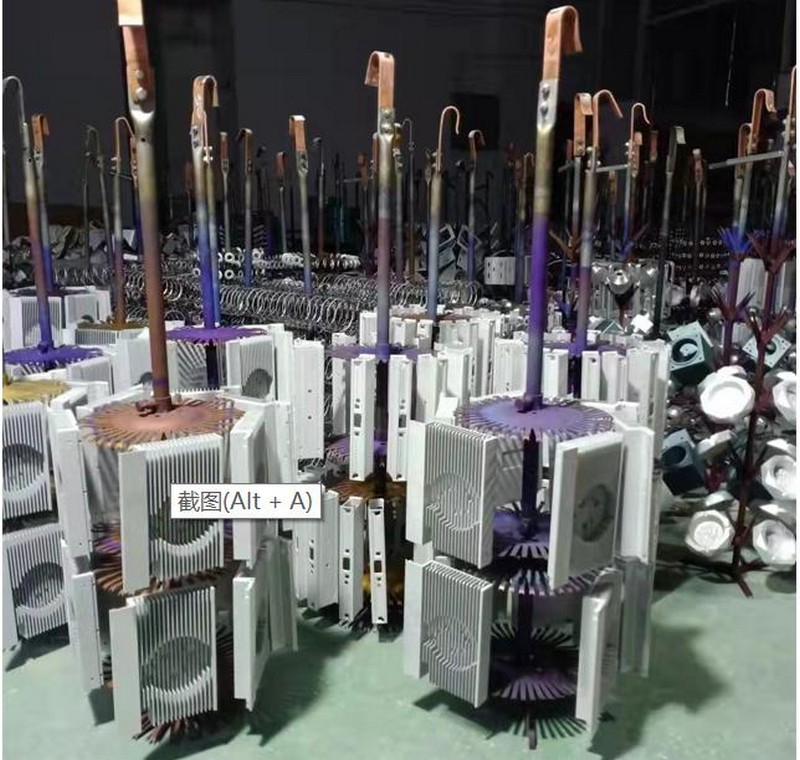

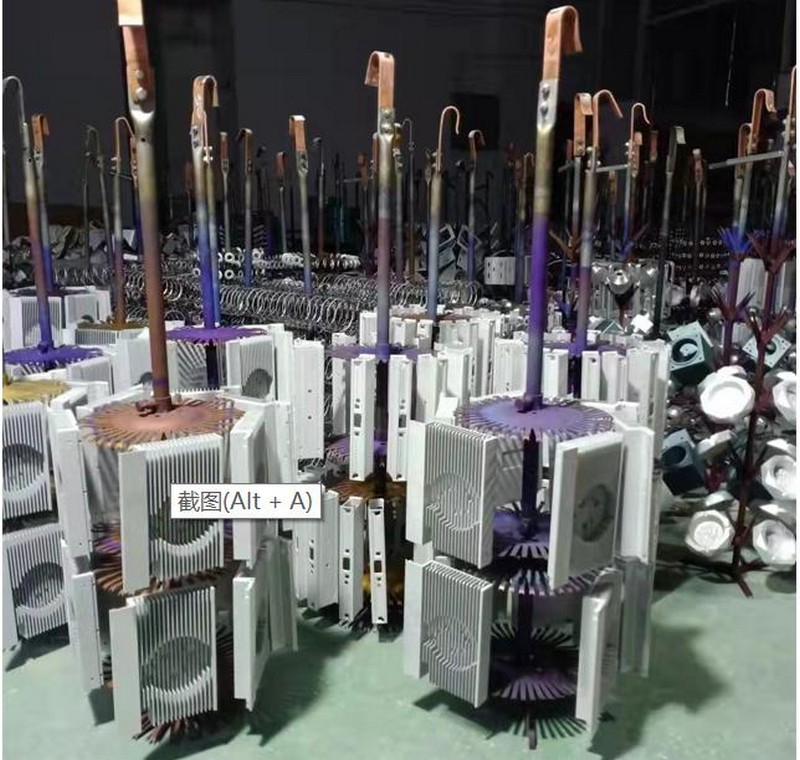

Metal surface treatment mainly includes metal electroplating, anodizing, wire drawing, sand blasting, polishing, powder spraying, painting, etc.

(1)Metal plating and anodizing are the most common, which can increase the physical properties of aluminum parts and meet the needs of various colors.

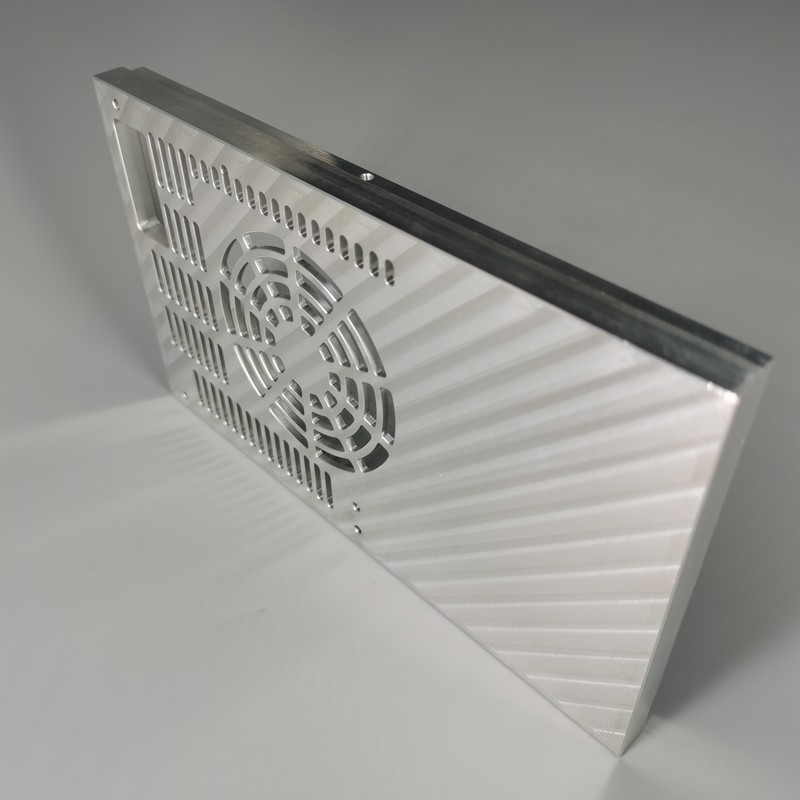

(2)Wire drawing can make the surface have smooth and continuous lines and improve the beauty of parts.

(3) Sand blasting can clean the metal surface and roughen the aluminum outer layer. After sand blasting, it can increase the roughness and improve the adhesion ability.

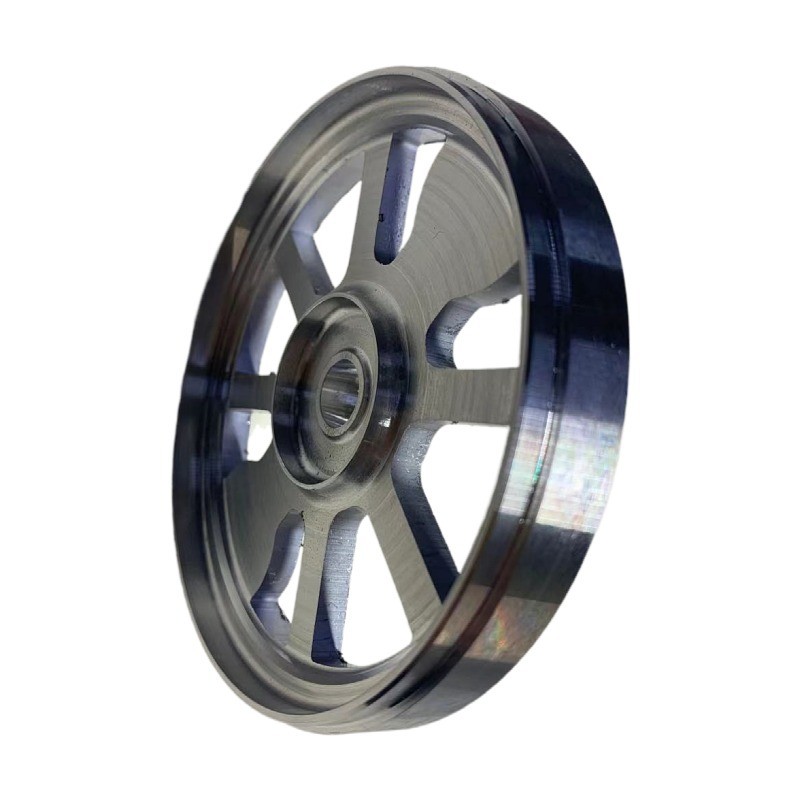

(4)Polishing is to polish the outer layer through mechanical,chemical or electrical means to make the surface smoother and brighter.

(5) Powder spraying is non-toxic and does not pollute the environment,has good quality, high adhesion and mechanical strength, and corrosion resistance.

Product Parameters:

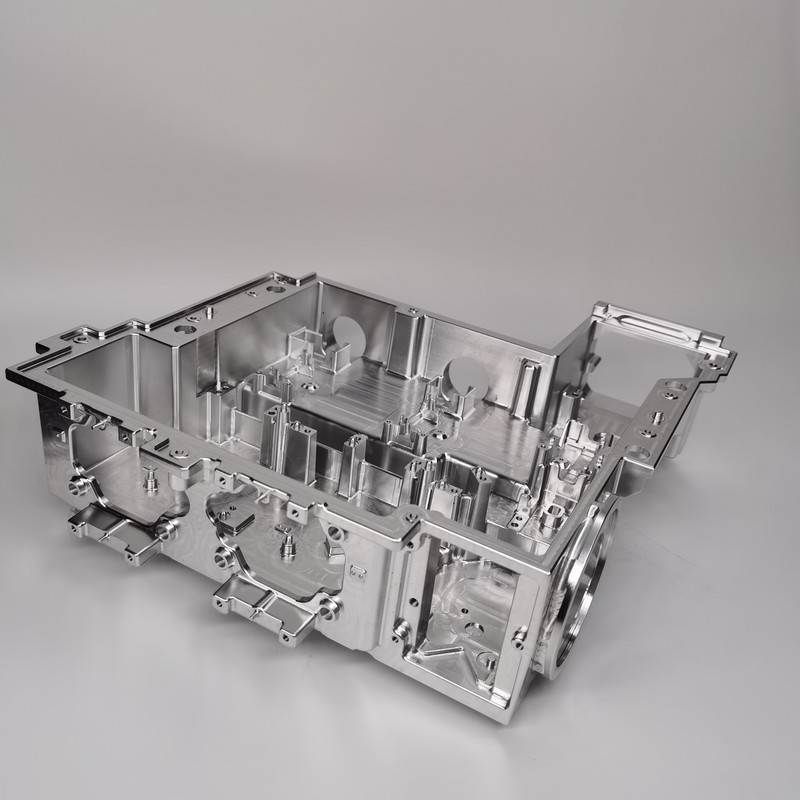

(1)Type:High Precision Surface Finishing Metal Parts For All Industries Manufacturing

(2)Material:Plastics ABS,POM,PEEK,PVC,UPVC,UHMW,Nylons,ULTEMS,PC,PMMA,PPS,PA

(3)Surface finishing:Anodized,Oxide,Plating,Brushing,Polishing,galvanized,

spraying,Painting,Tinted,,Logo&Symbol,Chromed & Metallizing,Powder Coat,Eletrophoresis,

Sandblasted&Bead blasted,Heat treatment,Blacking

(4)Inspection tools:Calipers,Thread Micro caliper,Projection,Pin gauge

(5)Accurancy:±(0.001-0.1)mm

(6)Model Number:OEM

(7)Certificate:ISO9001:2015,ROHS,SGS

Application :

Domestic Appliances, Lighting, Industrial Accessories, Electronic Products, Animation, Aerospace, Bathroom, Medical Instruments, Machinery, Car and Truck Parts.